Wire Arc Spraying is excellent for applications that require a heavy coating deposit, giving superior bond strengths and low porosity levels at high spray rates therefore, it is well suited for dimensional restoration of both mis-machined and worn parts.

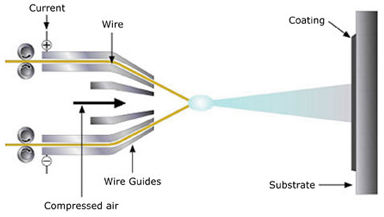

Wire Arc Spraying is a form of thermal spraying where two consumable metal wires are fed independently into the spray gun. The contact of the wires creates an arc. The arc produces such a temperature that is transforms the wires into a molten state, which is then deposited onto, a substrate at which point the impacting particles rapidly solidify to form a coating.

Benefits of Wire Arc Spraying

- High thickness build up Strong Adhesion

- Uniform coating “Cold process” minimal distortion

- Highly reliable

- Transportable equipment

- Suitable for most substrate types

- Extend service life

Coating Characteristics

- Dense Coatings

- Anti-wear

- Anti-corrosion

- Repair of mis-machined components

- Restoration

- Pure Metals

- Alloys

Many base materials can be mirrored which once again shows it suitabilitu to repair and restore components.

On site solutions

Due to the portable nature of the wire arc equipment, on site wire arc spray coating is also possible and at Celcoat we have extensive experience in performing on site repairs and reclamation

Celcoat’s wire arc spraying solutions have proven to be a cost efficient process that offers high variety of reliable coating solutions