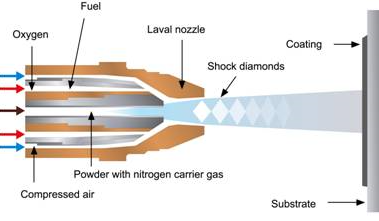

High Velocity Oxygen Fuel (HVOF) coating is the process by which oxygen and a fuel gas are combined within a combustion chamber where they are ignited and combusted continuously.

This Creates a high Velocity that propels the particles, which partially melt int the stream and deposit onto a components surface exceeding the speed of sound.

HVOF coating characteristics of

- Very low porosity

- Exceptional wear resistance

- Fine surface finishes

- Optimum hardness

- Excellent bond strenth

- Superb corrosion resistance

- High coating thickness

Materials Deposited

The heat and spray pressure of HVOF allows the deposition of material with high hardness characteristics that further enhance friction reduction such as:

- Tungsten carbide

- Cobalt alloys

- Chrome Carbide

- Ceramic alloys

- Nickel alloys

- Stainless steels

It is also a preferred technique for spraying high corrosions resistance alloys such as Hastalloy and Inconel.

Benefits of HVOF

- corrosion resistance

- high wear resistance

- sliding and abrasion

- oxidation and corrosion

Industries

- power generation

- oil and gas processing

- paper and pulp

- steel rolling glass processing

- pump and valve manufacturers

- railway and sea transportation

Coatings produced using HVOF have outstanding characteristics, even above other spray processes and here at Celcoat we have the technical experience and now-how to provide you with a first class service to solve all your coating requirements.