The Plasma Spray coatings process is the most flexible of the thermal spray processes at Celcoat asit allows for a wide range of powders and applications.

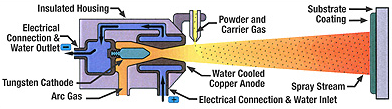

A highly energetic plasma jet melts and accelerates sprayed material particles allowing deposition of the coating. The heat source (plasma) is created by an inert gas superheated by a dc arc. The powder feedstock is then intoduced via an inert carrier gas and is accelerated towards the work piece by the plasma.

Deposits with a thickness from just a few micrometers (um) up to several millimetres can be produced using a variety of materials, including metals and ceramics.

Benefits of Plasma Spraying

- Ability to spray with a wide range of materials

- Flexability to coat onto both small and large components

- Minimial distportion of the substrate

- Excellent adhesion with some coatings

- Excellent control of coating thickness

- High Dense and strong coatings

Coating Characteristics

- Corrosion Protection

- Wear Resistance

- Electrical resistivity and conductivity

- Heat and Oxidation resistance

- Temperature Management

Materials Deposited

- Almost any metallic or ceramic

- Oxide ceramics like Chrome Oxide and Alumina

- Nikel

- Molybdemun

Industries

- Automotive

- Power Generation

- Oil and gas processing

- Paper and pulp

- Steel rolling

- Glass processing

- Pump and valve manufactures

- railway and sea transportation

Plasma spraying coatings are generally more denser, cleaner and tougher than other thermal spray process (other than HVOF) and the range of materials and applications make this process the most versatile